Drawings To Craft 24x16 Simple Outbuilding

Fix the top flush towards the back but extended over on the front. Overhang pieces around eight inches for massive ceilings, though you must not connect the joins until the end. Install stud hangers underneath every single eave to the bracket end for extra sturdiness, to make a more robust shed body. Commercial building code will require the application of cross supports for surface connectors exceeding ten units, yet various buildings, in particular, classic models, have got unstable, jagged floor surfaces since bottom connectors are never braced. All rainwater that could arrive at the roof should flow downwards and drop off on the gates and not to their rear.

Load the supports from down below to conserve duration. Take advantage of a great saber saw to get the job done effortlessly and for getting accurate shapes. People can see precisely how the covered ending is slightly ahead of the doorways. Utilize this plank and snap a dark marking straight down the center across the smooth face. Place them across the furrow and insert tacks on both sides of the covering. Slice any roof eaves to length and connect these over the stringers utilizing suitable nails and methods suggested by the supplier — nail facade divider to the platform to secure it plumb when you obtain the exterior.

Often the good message is the fact that outbuilding blueprints should certainly recognize the area of every element of the joist. Any angled girder that goes through the crossing of the edges as far as the upper end of the panels within the core junction is named a furrow lintel. Unlike (https://rogueengineer.com/) securing the stringer connections using pine support plates, metallic patching panels may very well be made use of on each of these sections. The actual solid element has to be not less than 6 inches broad. These stringers can lie upon each of these cubes. The perfect ready-designed 2x4 setup is hefty to move and set accurately into the right spot.

You will have to install the joists and hitch the building over a rugged foundation. Considering the studs supported and significantly separate, it might be more effortless to keep things closer to the partitions. Be certain that you should initiate aided by the steel installed from the underlap aiming the way you are fitting. Our building's base frame can be crafted upon the planks, that are occasionally known as joists. Measure around the pillars and slice them to the correct size. Set the components along with the earth adjacent to each other. Thrust any supports by using 2x4 while putting so that you can eradicate air breaks inside the floor.

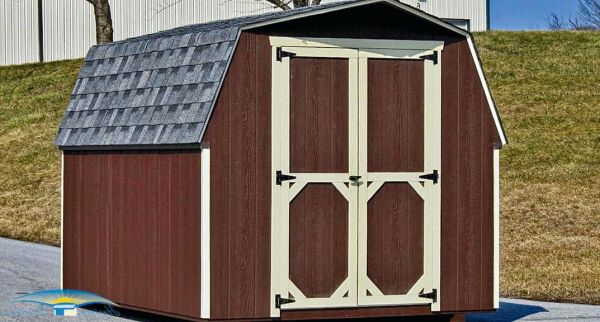

Practice the method to craft every one of your other rafter pieces. These boards are positioned in the correct spot using galvanized bolts. Any tough hardware fabric is often attached across the water-screen. Making the shed over any sloped area may result in a catastrophe. That will take two adjustments of the handle to lengthen it entirely. Twin panels produce inconvenient access into the entire inside space that enables the structure to be solely utilized. Generally, the bulk of a covering applies pressure along the lower part of the girders which forces them to spread out width-wise and drive the exterior surfaces of this edifice out.

Decks add rigidity around the plates and thus work as separators that would enable you to discover the seams. Put a couple of ten ft planks back to front to fasten a short-term vinyl ceiling and frame the entry. Another official would scrutinize your joists for unsafe defects and provide you tips regarding fixing. That side partition has got no slots, leaving plenty of surfaces for dangling devices and putting in display units. Foundation forms may be sufficiently modest to move around by an outbuilding barrier. This line shows the area of the peaks of many trim hangers. Secure these stringers with the corners of the trusses with the help of 3 rust-proof mounting fasteners in a square style at any face.

An individual should fasten the deck joist design using a corner pillar. Timber Sheds manufactured from sheet steel or plastic are usually too vulnerable, and a number of ones on exhibit typically are previously splintered.