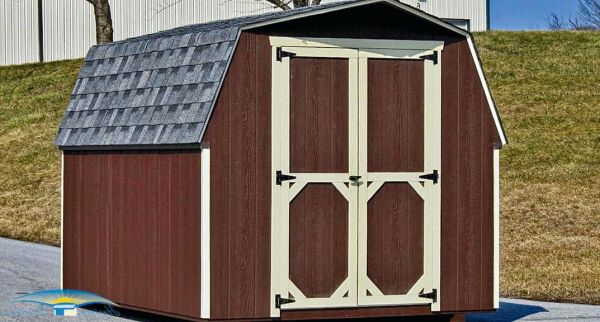

20x10 Storage Shed Making Diagrams

The craft that frames on the well-drained ground to help it remain for a more extended period. Place three 10 feet planks on the side to brace a transient rubber ceiling and build the front door. Often, for dual panels, one locks one entrance to the jamb, after which the adjacent doorway connects against the first. Always ensure you begin the process making use of the material used in the section passing the direction you're putting. You'll need to add the pillars and hook up the building over a solid floor — Peg your upper couple of trimmers over the ridge block by using bolts through a gable area. This transversal truss that extends by the connection of the furrows near to the apex of these barriers at the core cusp is addressed as a channel board. That might take two adjustments of the holder to extend ( outdoor shed making blueprints 16 x 4 ) it completely. Chop any ceiling eaves to length and screw them all to the trimmers by using rust-proof fasteners and steps recomm...